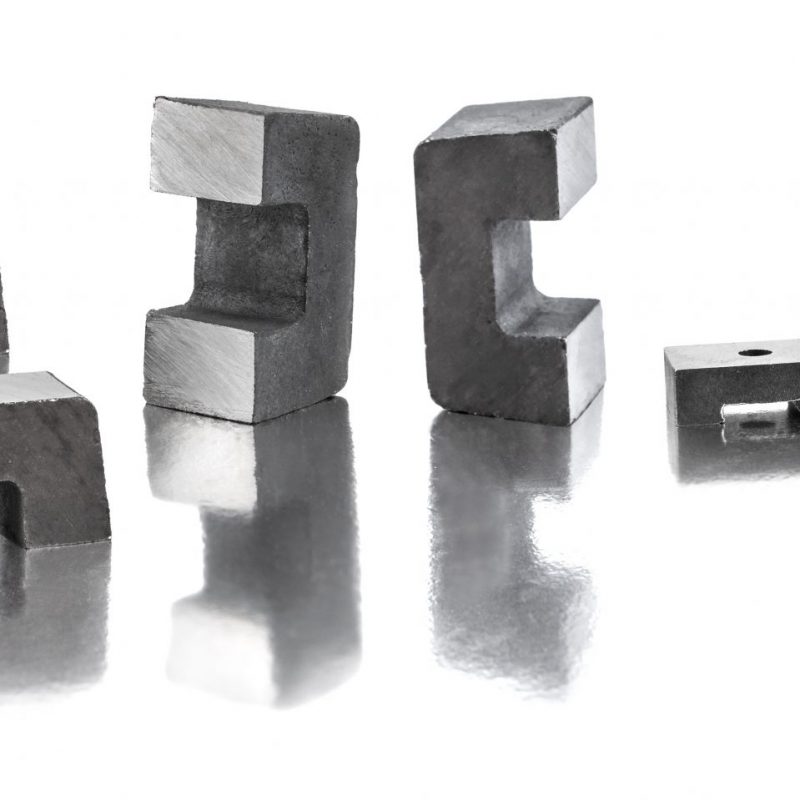

Neodymium Iron Boron

Neodymium Iron-Boron magnets are sintered magnets composed of Neodymium, iron and bore powder. A nickel, zinc or epoxyd coating is necessary to protect this material against corrosion (due to agressive environment). These are the magnets with the highest specific energy (BHmax) at room temperature. Their density is 7.5.

Read descriptionDescription

Neodymium Iron Boron range

HOLDING FORCE

- Magnetic force is optimal when the magnet is in contact with a mild steel frame, flat, clean and rather thick. It is lower with allied steels and cast iron (less 30% for cast iron).

- It is lower in presence of an air gap (space between the part to magnetize and the polar face of the magnet).

- It is decreasing by 0.22% every degree C by propitious circuits (see besides curve).

Induction On surface

- The maximum value of induction in surface at 20°C is about 5000 Gauss for Neodymium Ferbore flat pot magnets.

- This value is decreasing by 0,22% every degree C when temperature is increasing

MECHANICAL RESISTANCE

- These ceramics are very fragile.

- They must be handled carefully.

- To avoid magnets attraction during handling we advise to put them on a mild steel plate.

- Do not shock or squeeze.

RESISTANCE TO TEMPERATURE

- Maximal working temperature is about 80°C, because of Hcj sensitivity to temperature (0.66% every degree C).

- The induction losses are reversible so far we stay in the limit of working temperature of the material. It is 80°C in open circuit with standard grade. There are several NdFeB grades up to 180°C.

Ressources

Material Sheet Neodymium Iron Boron

Download the file

Neodymium Iron Boron

Find out more about the main characteristics, composition, applications and uses of Neodymium Iron Boron magnets.

Read more

Our materials

Looking for a particular material? Check out our product sheets.